Manufacturing across Virginia is accelerating, from advanced machining in Lynchburg to aerospace and robotics in Northern Virginia to shipbuilding along the coast. But as exciting as growth is, one challenge consistently rises to the top for small and mid-sized manufacturing companies:

Finding, developing, and keeping the people who power your business.

At PeopleWorX, we believe that strong businesses start with people. And nowhere is that more true than in manufacturing, where skilled labor, safe practices, and operational efficiency directly impact production outputs and long-term growth.

Today’s Virginia manufacturers need more than payroll processing, they need strategic workforce development backed by HR expertise and supported by modern workforce technology.

Below, we break down the trends shaping manufacturing labor in Virginia, key challenges employers face, and how organizations can strengthen hiring, training, and retention in a competitive environment.

Why Workforce Development Matters for Virginia’s Manufacturing Industry

Virginia is home to more than 6,000 manufacturers, and the workforce powering those businesses is rapidly evolving.

Statewide Growth & Changing Skill Needs

Automation, robotics, and advanced materials are reshaping job requirements. Manufacturers need:

- Technicians with cross-functional skill sets

- Safety-conscious employees who understand changing compliance regulations

- Talent willing to learn continuously as technology evolves

This puts pressure on SMB manufacturers who may not have a dedicated HR team, or the time to manage recruiting, training, compliance, and workforce planning internally.

Aging Workforce

Like much of the U.S., Virginia’s manufacturing workforce is aging. A significant portion of skilled workers are nearing retirement, creating talent gaps that smaller manufacturers struggle to fill.

Competition for Skilled Labor

Manufacturing companies are competing not only with each other, but with:

- Construction firms

- Logistics providers

- Government contractors

- Tech and trade employers

This competition increases wage pressure, benefits expectations, and demand for strong onboarding, training, and career pathways.

The Biggest Workforce Challenges Facing Virginia Manufacturers

1. Recruiting Qualified Workers

Skilled labor shortages and changing skill needs make it hard for small manufacturers to find qualified candidates. Many rely on manual recruiting processes, outdated job descriptions, or inconsistent hiring workflows.

2. Training and Upskilling

Employees often need:

- Safety and OSHA training

- Equipment certifications

- Ongoing compliance updates

- Specialized production training

Without streamlined LMS (Learning Management System) capabilities, these requirements become difficult to track.

3. Compliance Risk

Manufacturers must track labor hours precisely, manage shift differentials, overtime rules, and comply with multi-state or locality-specific regulations, especially for Virginia businesses near the Maryland, North Carolina, or D.C. borders.

4. Retention Issues

Companies with inconsistent onboarding, unclear career paths, or unreliable payroll processes experience higher turnover, increasing recruitment costs and slowing production.

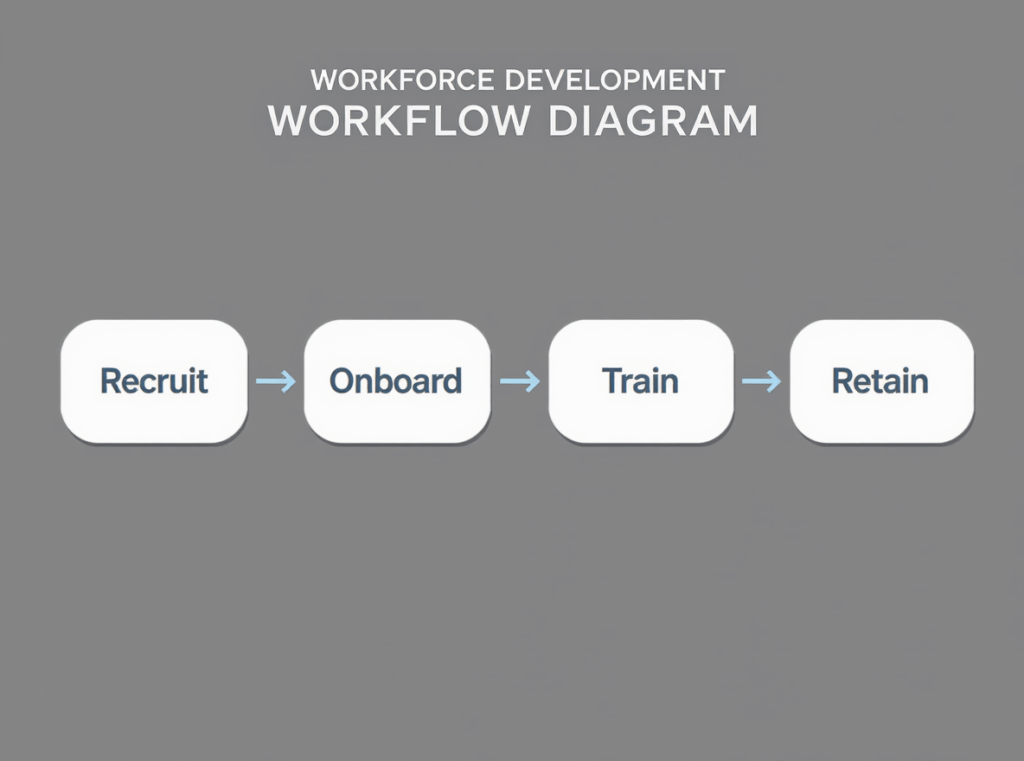

Workforce Development Strategies That Help Virginia Manufacturers Grow

Here’s how small and mid-sized manufacturers can strengthen their workforce strategy.

1. Build Stronger Talent Pipelines

Manufacturers should partner with:

- Virginia community colleges

- Career & technical education (CTE) programs

- Local workforce boards

- Apprenticeship programs

Listing the top talent sources ensures a steady pipeline into junior and mid-level roles.

2. Modernize Recruiting & Onboarding

Automated applicant tracking (ATS), streamlined onboarding, and digital new-hire forms create a positive first impression and reduce administrative burden.

PeopleWorX Recommendation:

Use an integrated applicant tracking and onboarding system to remove paperwork bottlenecks and ensure new hires are productive faster.

3. Invest in Training & Upskilling

Consistent training builds confidence, reduces safety incidents, and supports Virginia manufacturers in keeping pace with new technology.

A modern LMS helps you:

- Track certifications

- Ensure OSHA compliance

- Provide micro-learning for new equipment

- Deliver training digitally across shift schedules

4. Strengthen Payroll Accuracy & Scheduling

Manufacturing payroll is unique. Shift differentials, overtime rules, multi-location operations, and job costing require precise, error-free systems.

This is where PeopleWorX makes the biggest difference, by combining modern workforce tools with a dedicated payroll and HR representative, not a call center.

5. Build a People-First Culture

Retention improves when employees feel connected and supported. Workforce development is not only training, it’s engagement, performance management, and clarity in expectations.

Tools like:

- Employee surveys

- Performance reviews

- Recognition programs

…help Virginia manufacturers build workplaces where people stay.

The PeopleWorX Difference for Virginia Manufacturers

Many workforce challenges manufacturers face aren’t solved with software alone. You need a partner.

PeopleWorX provides:

- A true dedicated representative who learns your business

- Payroll precision with job costing, shift rules, and allocations

- Workforce management that integrates time & labor, benefits, and HR

- LMS for training and compliance

- A full HR framework (FrameWorX™) designed for small and mid-sized Virginia businesses

Manufacturers across the region, from multi-shift operations to family-run shops, choose PeopleWorX because we help them navigate today’s workforce complexity with confidence.

Frequently Asked Questions

Q1: Why is workforce development important for manufacturing companies in Virginia?

A strong workforce strategy helps manufacturers fill skills gaps, stay compliant, and maintain production efficiency as technology and labor demands evolve.

Q2: How can small manufacturers compete for skilled workers?

By improving recruiting workflows, offering training pathways, and building a strong employee experience—from onboarding to accurate payroll.

Q3: What training is essential for manufacturing employees?

Manufacturers should prioritize OSHA training, safety certifications, equipment training, and ongoing compliance education. An LMS simplifies tracking.

Q4: Why do manufacturers need a dedicated payroll/HR representative?

Manufacturing payroll is complex. Having a dedicated rep ensures compliance, accuracy, and support without call center delays.

Q5: How can PeopleWorX support workforce development in manufacturing?

PeopleWorX provides integrated HR, payroll, timekeeping, training tools, and hands-on expert guidance tailored to Virginia manufacturers.